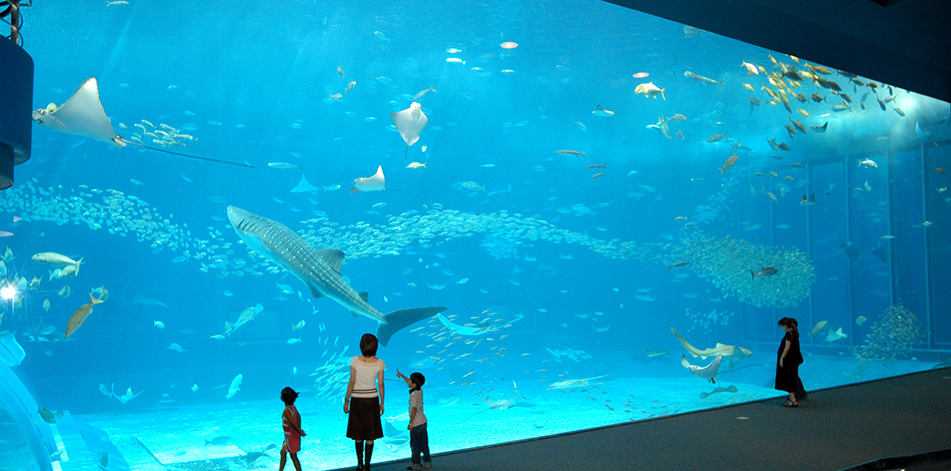

Nippura produces highly transparent and extremely strong Acrylic Panels. Using proprietarty methods we form, bond, join, color, stabilize, and blow amazing panels for the Aquarium Industry. Our core values: Transparency, Durability, & Safety. Methodology and technical prowess forged by years of development has allowed us to create other acrylice products such as ultra faithful projection screens, acoustic noise sheild panels, hefty clear sea walls, and even fantastical art sculpture piece.

透明度

TRANSPARENCY

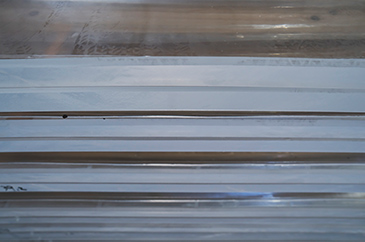

Our unique casting method involves the production of relatively thin, 30-40mm thick panels in very high quality and productive yields, then casting them together to form panels over 750mm thick. Regardless of the angle of the viewer, Nippura Aqua Walls provide pure clear views only possible with this unique technology. Exacting casting, thickness control, and polishing techique underpin our success, while innovation in proprietary tools and machinery keep us aways pushing forward with increases in productivity and competitiveness. Site Chemical Bonding Technology developed to succeed in even extreeme construction site conditions allows our Site Technicians to confidently create the worlds next largest panel or most complicated configurations. We also have cultivated over the years very dependable and respected waterproofing and sealing products that are trusted by Aquarium worldwide to keep the inhabitants healthy, the buidling structure sound, and maintenance running costs low. Nippura is known in the industry for its comprehensive solutions which provide not only the clearest views, but also security and peace of mind.

耐久性

DURABILITY

As Aquariums have became larger and larger, the need for panels with exacting quality has become more and more important, as in most cases it is impossible to replace the panels once, the construction of the building is completed. Therefore our production specifications and quality is geared to meeting the life of the aquarium building. One of our unique characteristics is that whether domestically or internationally, we only use our own factory technicians for all aspects of production and installation. Safely handling and placing the several hundred tons pieces of acrylic, waterproofing and protecting football field sized concrete tank from leakage and corrosion, and sealing the entire package into a vessel that loses not even one drop of water, are all made possible by the skills and the discipline of Nippura Factory Technicians.

安全性

SAFETY

The Aquariums produced by NIPPURA are healing spaces, and places where accidents should never occur. As aquariums become larger, aquarium panels must be uniformly strong, durable and stable to safely hold thousands to tens of thousands of tons of water for decades. We strive to maintain safety by making full use of the know-how thats been cultivated over many years by alwasy advancing technical capabilities.

One of the factors supporting our safety is our heat treatment annealing technology that further increases the strength of the molecular bonds and purity of the cast and the bonds. This treatment technlogy also increase the total transmittance for clearer panels.

When bonding is performed during on-site construction, annealing treatment is similarly performed while being monitored 24 hours a day. Although this process takes a long time, it is essential because we strive for the highest quality viewing clarity and the utmost strength for safety.